VERTICAL TURNING CENTERS

Hwacheon’s vertical turning centers are available in many different vertical CNC lathe lineups, ideal for your mid- to large-size applications.

+ 371 2 911 80 85

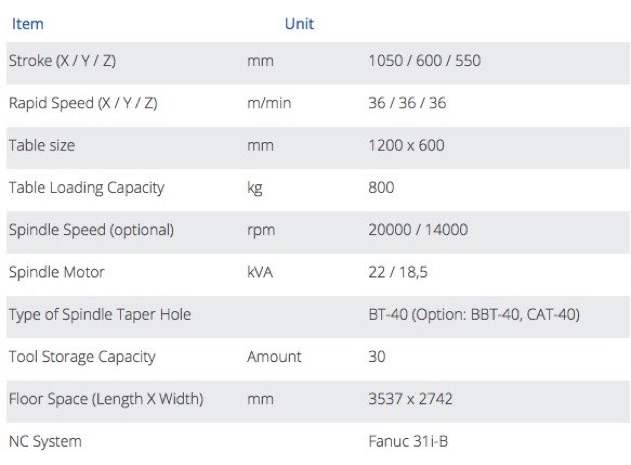

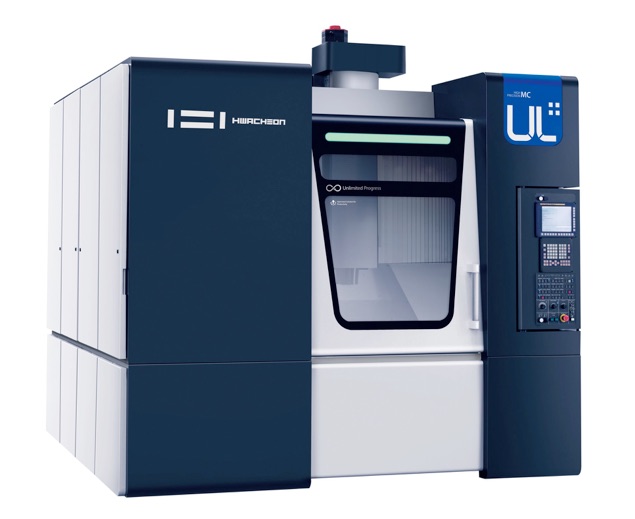

SIRIUS-UL+

HIGH SPEED VERTICAL MACHINING CENTER FOR DIE AND MOLD

"HWACHEON PERFORMANCE LEAVES COMPETITION IN THE DUST - THIS IS THE BEST DIE AND MOLD CENTER YOU CAN GET, PERIOD."

Each SIRIUS-UL+ machining center is manufactured to perfection with Hwacheon's workmanship that is the quality recognized and envied by everyone in the industry; and it guarantees to give you a perfect result every time.

The high performance spindle which integrates Hwacheon's Oil-jet Cooling technology ensures consistent quality result after hours and hours of operation, while the machine's Optimal Machining system gives you a total production solution, from tool selection to final product.

SIRIUS-UL+ is designed using 3D simulations and the FEM analysis to achieve structural rigidity which can translate to quality product results; while the Hwacheon-designed machining software components enhance safety and the work efficiency in your organization. The SIRIUS-UL+ is configurable with many different options so that it can integrate better in your work environment and application .

The Hwacheon Machining Software Components

The Hwacheon's developed machining software monitors different variables related to the work environment and machining conditions and makes adjustments for best quality results and optimum work efficiency.

Rigid Bilateral Gate Structure

Machine Frame The gate structure firmly supports the x-axis drive and diverts the load, vibration, and heat from the upper section of the machine evenly throughout the frame-the feature which helps too keep the feed drive stable after hours of operation. Also, the short distance between the X-axis drive and the tool's contact point is a plus for maintaining the rigidity and for enhancing the machining precision.

High-performance spindle design

The spindle integrates the motor to limit vibration, noise, and power loss at high speed rotation. The jet of oil is injected directly onto the spindle bearing for effective cooling, and the motor and the spindle assembly are jacket-cooled to limit the displacement caused by heat. To achieve greater precision, the spindle constantly monitors for possible thermal displacement and makes necessary adjustment in real time.

Adrese: Stabu iela 80, Rīga, LV-1009

Tel/fax: 67288548

Mob. 29118085

e-mail: sales@baltictools.com